Janjgir-Champa, India

495552

info@manuindiaearthing.com

Business Hr. 8:00 - 7:00

+91 73898 49969, +91 72250 22268, +91 72250 22286

Call Now

495552

Business Hr. 8:00 - 7:00

Call Now

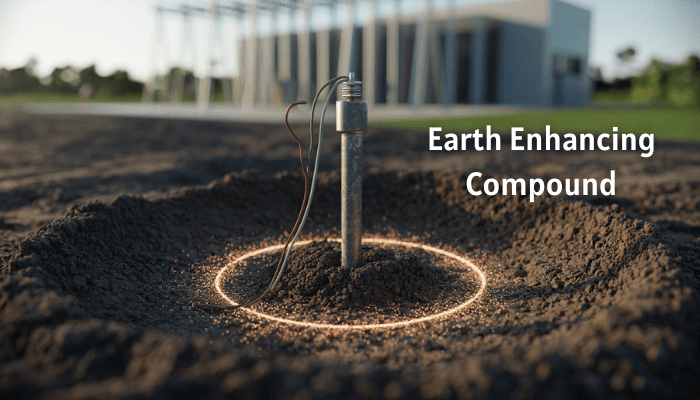

India’s variety of climate zones, from humid coastal areas to dry inland areas, presents challenges in maintaining consistent electrical earthing. The grounding system has to be stable in order to guarantee the safety of electrical installations in residential and industrial applications. This is where Earth Enhancing Compounds come in.

They not only improve the conductivity of soil but also improve the efficiency and life expectancy of an earthing system. With Manu India Earthing’s Installation Service, you can ensure a reliable and long-lasting earthing solution tailored to your specific environmental conditions.

In this blog, we will discuss what Earth Enhancing Compounds are, how they work, and why they are an important part of new earthing systems in India.

An Earth Enhancing Compound is a specially formulated conductive material that lowers the earth resistance of an earthing system.

In contrast to the traditional methods, Earth enhancing compounds are engineered for consistency, longevity, and performance. They are a useful tool when dealing with areas of high soil resistivity, such as rocky, sandy, and dry regions, which include much of India.

At Manu India Earthing, we provide high-performance compounds engineered to adhere to high Indian and international standards to ensure that all grounding systems function consistently even in adverse conditions.

India has a varied set of soil resistivity problems. In hard rocks, sand, or arid soils, it is a common problem to achieve low-resistance earthing. The seasonal changes, like frequent rains or droughts, tend to raise the soil resistance even further.

Utilizing Earth Enhancing Compounds serves to address these issues and offers a sound and durable solution.

The primary function of an Earth Enhance Compound is to decrease the earth’s resistance surrounding the electrode. When the compound is properly placed, it will fill the voids from the electrode to the surrounding earth, increasing conductivity and moisture retention.

When using these Compounds in Indian Electric earthing systems, there can be some technical and safety benefits:

If you’re interested in high-quality (certified and trusted) compounds appropriate for Indian environmental situations, go to Manu India Earthing to get the best.

In India, finding the right Earth Enhancing Compound is important because of the broad range of soil types that exist, from very dry desert areas to coastal regions.

This is a compound made from natural bentonite clay It will swell when water comes in contact with it and generally provides more moisture retention than other compounds.

Graphite-based compounds are noted for their high conductive ability and long-lasting performance.

These Compounds are well-suited to industrial zones, commercial buildings where the grounding must remain constant under varying weather conditions, and substations.

Carbon-based compounds are augmented with conductive carbon particles and anti-corrosive compounds.

As such, this compound is often preferred by engineers and Earthing Electrode Manufacturers working on large-scale commercial projects.

Hybrid Earth Enhancing Compounds blend the conductive qualities of bentonite, carbon, and other conductive minerals to provide both moisture-holding capacity and high conductivity. A few Earthing Electrode Manufacturers provide hybrid compounds as an all-purpose option for any installation.

We offer a variety of compounds at Manu India Earthing to cater to various needs. Whether it’s a household user or you’re a commercial earthing electrode producer, you’ll find the perfect fit here.

When using the Earth Enhancing Compound to conduct electrical grounding, use of the compound should be used the right way and as well as the type of the compound.

An Earth Enhancing Compound is a conductive material applied on the earth around earthing electrodes to increase soil conductivity and lower the grounding resistance. It provides secure and economical electrical earthing, in particular on problem soils.

The compound reduces the resistance of the soil, holds water, and occupies air holes around the electrode. It forms a superior contact surface between the electrode and the earth around it and results in improved current outflow.

Yes, the majority of compounds are made to fit well in different types of soils, that is, in rocky, sandy or clayey soils. But the particular compound should be selected, upon soil testing and professional advice of your Earthing Electrode Manufacturers.

Quality compounds have durability of more than 10 years before they require replacement. The life span varies with the compound used, the soil, and the maintenance results.

Most of the compounds that are in the market nowadays are non-corrosive, non-toxic, and environmentally friendly. These aids are not harmful to the soil and the groundwater, and they fit even the national and international safety directives.

A reliable electrical earthing is much more than dropping a rod in the ground; it’s about ensuring the system will perform through the monsoons, dry times, and usage spikes. The compound has significant importance in ensuring this reliability.

Whether you are a homeowner, contractor, or earthing electrode manufacturer, it is wise to draw on the very best Earth Enhancing Compound to minimize risk, reduce maintenance, and enhance safety.

If you’re looking for high-performance, certified, and cost-effective earthing solutions, go to Manu India Earthing – India’s trusted name in advanced earthing technology.