Copper Bonded Earthing Rod

Our Products

Copper Bonded Earthing Rod

Contact Info

Our team is ever ready to address any queries! Please call the given number to avail our services!

+91 73898 49969,

+91 72250 22268,

+91 72250 22286

24/7 Support for Your Business

Info File

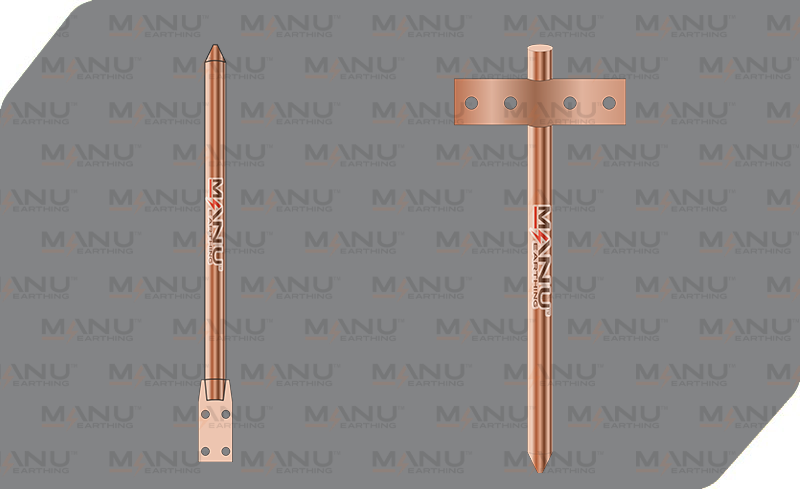

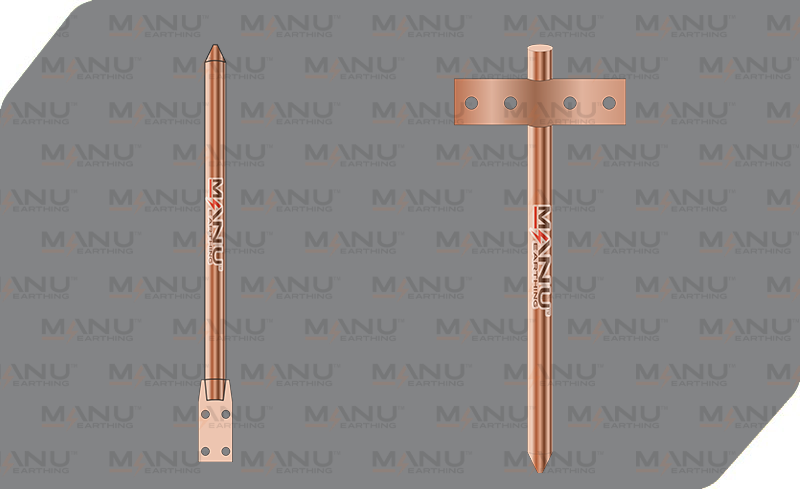

Copper Bonded Earthing Rod – Features, Uses & Technical Details

One of the most prevalent earthing options used in electrical installations is a copper-bonded earthing rod. At Manu Earthing – Earthing Electrode Manufacturer, we provide rods that fuse the high conductivity of copper with the strength of steel, achieving excellent fault current dissipation and corrosion resistance. This renders them a perfect selection for residential, commercial, and industrial grounding systems.

What is a Copper Bonded Earthing Rod?

Copper Bonded Earthing Rod is produced through the process of molecularly bonding a layer of copper to a low-carbon steel core. This fusion brings about the mechanical strength of the steel and the high conductivity of the copper. The rod must be compatible with soil conditions, soil moisture, and other environmental conditions, and maintain a low-resistance path to allow fault currents, lightning, or leakage current to safely enter the ground.

Technical Specifications of Copper Bonded Earthing Rod

These are electrical rods that are available in various sizes and specifications to fit diverse electrical requirements.

- Material Composition: Copper-bonded, electrolytic process low-carbon steel core.

- Copper Coating Thickness: Average diameter of 100–250 microns or more, which makes it durable.

- Rod Diameter: Diameters are commonly 14 mm, 16 mm, 17.2 mm, 25 mm and custom sizes.

- Rod Lengths: Exist in 1 meter, 2 meters, 3 meters and extended body with threaded couplers.

- Tensile Strength: Typically, more than 600 N/mm², which offers superior mechanical properties.

- Conductivity: Good conductivity as a result of the copper layer that provides good dissipation of current.

- Threading Option: Available in threaded and unthreaded designs for easy installation.

- Corrosion Resistance: The bonding to the copper layer stops peeling or cracking of the copper.

Key Features of Copper Bonded Earthing Rod

These rods are characterized by durability, performance and easy installation.

- Bonding made of pure copper is very resistant to corrosion.

- Strong and ductile steel core ensures long life.

- Maximizes the use of available length and diameter to match project requirements.

- Simple to set up with couplers and driving heads.

- Provides consistent low-resistance grounding.

- Superior conductivity for fault current dissipation.

- Long service life even in aggressive soil conditions.

- Customizable designs for different industries and applications.

Benefits of Copper Bonded Earthing Rod

A copper-bonded earthing rod is very useful in grounding systems due to the merging of copper and steel.

- Long-Lasting Durability: Copper bonding is used to provide resistance against rust and corrosion, which extends life.

- Cost-Effective Solution: Performs well at a reduced price when compared to pure copper rods.

- Mechanical Strength: The Core made of steel inhibits installation bending or breaking.

- Reliable Performance: Ensures a low impedance path for effective fault current dissipation.

- Safety Assurance: Lessens the danger of electrical accidents through safe grounding.

- Minimal Maintenance: When installed, it needs minimal or no regular maintenance.

Why Choose Copper Bonded Earthing Rod?

When deciding on a copper-bonded earthing rod, you would be on the right track of having one of the grounding solutions that are both safe and economical. In comparison to the old GI Earthing Rod or galvanized iron rods, which can easily get corroded and be rendered useless in a short time, copper-bonded rods last longer and are cheaper compared to solid copper rods. These are made out of a high-quality steel core, excellent copper coating, and their flexibility makes them the perfect solution for long-term and reliable earthing.

Features

- High-Tensile Steel Core – Offers excellent mechanical strength, enabling deep driving into all soil conditions.

- Electrolytic Copper Coating (Min. 250 microns) – Ensures uniform bonding, maximum conductivity, and resistance to corrosion.

- Molecular Bonding Process – Copper layer is permanently bonded to the steel core for long-lasting performance.

- Threaded Ends – Allows easy joining using couplers for extended depth installations.

- Durability – Capable of withstanding electrochemical reactions and harsh environmental conditions.

- ISI/IEC Compliant – Manufactured in accordance with international quality and safety standards.

Applications & Use Cases of Copper Bonded Earthing Rod

They are common in industries where they are applied in efficient and reliable earthing.

- Residential Buildings: To ground household wiring systems safely.

- Commercial Complexes: In order to safeguard electrical appliances, panels, and equipment.

- Telecommunication Towers: Offers grounding stability to eliminate signal disruption.

- Power Distribution Systems: Safeguards transformers, substations, and distribution lines.

- Lightning arrestors: Dry lightning efficiently into the soil.

- Renewable Energy Installations: Applied in wind power and solar power.

- Data Centres & IT Infrastructure: Ensures uninterrupted performance of sensitive electronic equipment.

FAQs

An adequately fitted rod might even last many decades, owing to the corrosion-proof copper coating.

Yes, since they are made of a steel core, they can be pushed into difficult soil with the assistance of driving heads and couplers.

Yes, they offer great lightning dissipation, thus, quite useful in lightning protection systems.

They are usually economical to maintain when they are installed and can be used as a long-term solution.

Re-use is not advised because they may get corroded during the removal process, and their efficiency will be decreased.

Our Products

Copper Bonded Earthing Rod

Contact Info

Our team is ever ready to address any queries! Please call the given number to avail our services!

+91 73898 49969,

+91 72250 22268,

+91 72250 22286

24/7 Support for Your Business

Info File

Copper Bonded Earthing Rod

A Copper Bonded Earthing Rod is a high-performance grounding solution designed to provide a low-resistance path to earth, enhancing the safety and efficiency of electrical systems. Manufactured with a high-tensile steel core and coated with electrolytic grade copper, these rods offer exceptional conductivity and corrosion resistance, making them ideal for long-term grounding applications.

Features

- High-Tensile Steel Core – Offers excellent mechanical strength, enabling deep driving into all soil conditions.

- Electrolytic Copper Coating (Min. 250 microns) – Ensures uniform bonding, maximum conductivity, and resistance to corrosion.

- Molecular Bonding Process – Copper layer is permanently bonded to the steel core for long-lasting performance.

- Threaded Ends – Allows easy joining using couplers for extended depth installations.

- Durability – Capable of withstanding electrochemical reactions and harsh environmental conditions.

- ISI/IEC Compliant – Manufactured in accordance with international quality and safety standards.

Applications

- Electrical Grounding Systems – Offers safety from electrical faults and stabilizes voltage levels.

- Lightning Protection Systems – Acts as the primary earth termination, ensuring safe dissipation of lightning surges.

- Power Stations & Substations – Maintains system integrity and personnel safety during faults.

- Telecommunications Infrastructure – Grounds towers and antenna systems, protecting against surge damage.

- Oil & Gas Industry – Minimizes the risk of sparks and static discharges in sensitive areas.

- Renewable Energy Systems – Provides earth continuity for solar panels and wind turbines.

| Rod Dia (mm) | Total Length (mm) | Terminal Size (mm) |

|---|---|---|

| 14 | 1000 | 32 x 5 |

| 14 | 2000 | 32 x 5 |

| 14 | 3000 | 32 x 5 |

| 16 | 1000 | 32 x 5 |

| 16 | 2000 | 32 x 5 |

| 16 | 3000 | 32 x 5 |

| 17 | 1000 | 32 x 5 |

| 17 | 2000 | 32 x 5 |

| 17 | 3000 | 32 x 5 |

| 25 | 1000 | 40 x 5 |

| 25 | 2000 | 40 x 5 |

| 25 | 3000 | 40 x 5 |

| 32 | 1000 | 40 x 5 |

| 32 | 2000 | 40 x 5 |

| 32 | 3000 | 40 x 5 |

| 38 | 1000 | 50 x 6 |

| 38 | 2000 | 50 x 6 |

| 38 | 3000 | 50 x 6 |

| 48 | 1000 | 75 x 10 |

| 48 | 2000 | 75 x 10 |

| 48 | 3000 | 75 x 10 |

| *Sizes can be customized | ||