HDG GI Earthing Rod

Our Products

HDG GI Earthing Rod

Contact Info

Our team is ever ready to address any queries! Please call the given number to avail our services!

+91 73898 49969,

+91 72250 22268,

+91 72250 22286

24/7 Support for Your Business

Info File

HDG-GI Rod: A Simple Introduction to Dependable Earthing and Lightning Protection

Ideally, to understand earthing and lightning protection, it is crucial to learn about technologies like earthing and conductors, which make the HDG-GI Rod so dependable for earthing and lightning protection.

A simple introduction to earthing and lightning protection will help in understanding the foundation of earthing and lightning protection. It will connect seamlessly to the technical details that follow and make the subject clear.

Earthing provides a safe conduction path through which electricity safely goes into the ground without causing damage to the connected system. In simple words, lightning protection is a safety system that protects the structure when lightning strikes.

Manu India earthing rods are used to safely dissipate electricity into the ground. This system protects the structure and people from incidents like electric shock and fire. In addition to proper earthing, increasing the life of equipment and enhancing safety, the suitability of earthing in educational places ensures the safety of students.

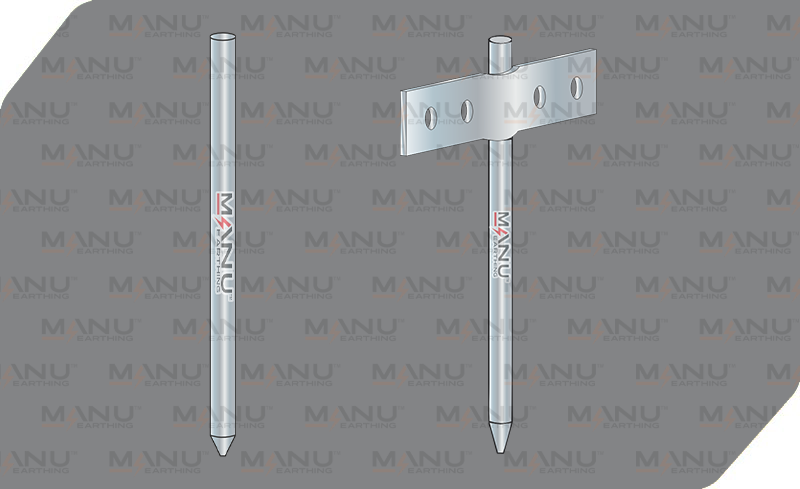

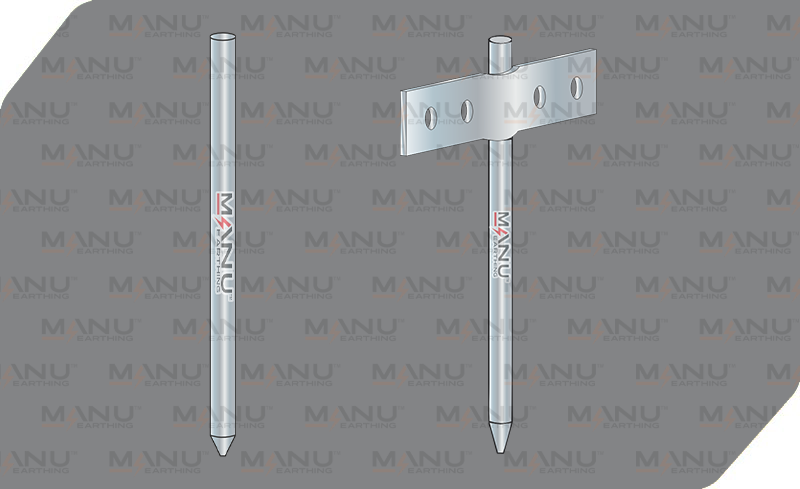

What is an HDG-GI Rod?

Manu India’s HDG-GI Earthing Rod is the main component of the earthing system. This product is easily connected with technical specifications and leads to its technical details.

Technically, an HDG-GI Rod is a Hot-Dip Galvanized Iron rod used for earthing. The rod is galvanized to make it strong and rust-free. This rod is inserted deep into the earth and transmits electricity to the ground. It forms the earthing point to ensure the safety of humans and equipment.

It is a very long and durable rod, known as the GI Earthing Electrode, that remains stable over long periods of time and is therefore used extensively as a simple and reliable earthing and lightning protection solution in schools, offices, homes, and other structures.

Technical Specifications of HDG-GI Rod

Knowing the technical specifications of the HDG-GI Rod, which includes size, material and quality, easily connects to the key features and helps in understanding the product even better

| Total Length (mm) | Terminal Size (mm) |

14 | 1000, 2000, 3000 | 32 × 5 |

16 | 1000, 2000, 3000 | 32 × 5 |

17 | 1000, 2000, 3000 | 32 × 5 |

25 | 1000, 2000, 3000 | 40 × 5 |

32 | 1000, 2000, 3000 | 40 × 5 |

38 | 1000, 2000, 3000 | 50 × 6 |

48 | 1000, 2000, 3000 | 75 × 10 |

(Custom sizes can also be provided.)

With such varied specs, miscellaneous needs of users are satisfied.

Key Features of HDG-GI Rod

The main properties of the HDG-GI Rod make it different and better than other options.

- Connectivity: The rod connects seamlessly to an existing structure or system to the beginning.

- Rustproof: The rod does not corrode due to rusting as it is galvanized.

- Shock Resistant: The rod is not vulnerable to physical shock and its strong steel assures durable performance.

- Temperature Tolerance: It can withstand high temperatures and seasonal changes and efficiently direct electricity to the ground.

- Easy Installation: It is simple to install and easy to use.

Moreover, the length and diameter of the HDG-GI rod can be chosen according to the application.

Advantages of HDG-GI Rod

The HDG-GI Rod offers significant benefits, making it a reliable grounding solution. These advantageous features make it a practical choice.

- Safety: It increases safety as it annuls the chances of being electrocuted or experiencing electric shock due to leakage.

- Lower Wear and Tear: The galvanized layer prevents it from deteriorating, thereby providing long-term protection to human lives and equipment.

- Protects Outdoor Structures: It protects outdoor structures like towers and buildings from lightning strikes.

- Value for Money: It creates a harmless environment both indoors and outdoors, thereby offering higher value for money.

Why Choose HDG-GI Rod?

Manu India HDG-GI Rod is the best choice because it seamlessly connects with the system and is of high quality. The rod is manufactured and carefully designed using an ISO-certified galvanization process, making it a reliable and cost-effective earthing and lightning protection system, suitable for the Indian climate. So, it is widely accepted in schools, domestic, and industrial use.

Applications and Uses of HDG-GI Rod

The HDG-GI Rod is particularly useful in specific applications.

Some of its significant use cases are for dependable earthing in:

- Schools: It is used extensively in school buildings, laboratories and administrative rooms.

- Homes: In residences, the rod protects different electrical appliances like PCs, fridge, and more.

- Industrial settings: It protects costly and sensitive machinery used in the workshops of several industries.

- Agriculture: Safeguarding water pumps and irrigation systems.

- Large structures and towers: Providing reliable lightning protection.

- Hospitals: Ensuring uninterrupted protection of costly medical equipment.

From urban households to industrial zones, the rod fits diverse installation requirements with ease.

FAQs

The rod is available in 1.8 m to 3 m in length. The thickness of the rod ranges between 12 mm and 14 mm.

No, the galvanized coating keeps the HDG-GI rod rust-free.

Yes, it is very suitable in schools due to its simple installation.

Yes, it is an important part of lightning protection.

The high quality of the rod is the biggest feature which is further accentuated by it rust-free galvanized coating.

Our Products

HDG GI Earthing Rod

Contact Info

Our team is ever ready to address any queries! Please call the given number to avail our services!

+91 73898 49969,

+91 72250 22268,

+91 72250 22286

24/7 Support for Your Business

Info File

HDG GI Earthing Rod

Hot-Dip Galvanized (HDG) GI Earthing Rods are highly durable grounding rods coated with a thick layer of zinc through the hot-dip galvanizing process. This coating protects the steel core from corrosion, making it suitable for use in various environments, including harsh and corrosive conditions. These Earthing rods are primarily used for grounding applications, providing a reliable and cost-effective solution for electrical safety.

Features

- Corrosion Resistance: Zinc coating ensures long-lasting protection against rust and corrosion.

- High Conductivity: Provides excellent electrical conductivity for effective grounding.

- Durable Construction: Made from high-quality steel for enhanced mechanical strength.

- Uniform Coating: Hot-dip galvanizing ensures consistent zinc coating across the surface.

- Easy Installation: Designed for straightforward and secure installation.

- Cost-Effective: Provides a reliable grounding solution at an economical cost.

- Customizable Sizes: Available in various lengths and diameters to meet specific requirements.

Applications

HDG GI Earthing Rods are widely used in electrical grounding systems across residential, commercial, and industrial installations. They provide reliable grounding for power stations, substations, telecommunication towers, renewable energy systems, and lightning protection setups. These rods are also employed in industrial facilities, oil and gas installations, and data centers, ensuring electrical safety, equipment protection, and stable grounding in various environments.

Advantages

- Long Service Life: Resistant to environmental wear and tear, ensuring longevity.

- Enhanced Safety: Reduces the risk of electrical faults and hazards.

- Versatility: Suitable for a wide range of applications across industries.

- Low Maintenance: Requires minimal upkeep due to corrosion resistance.

- Environmental Suitability: Performs well in corrosive and challenging environments.

| Rod Dia (mm) | Total Length (mm) | Terminal Size (mm) |

|---|---|---|

| 14 | 1000 | 32 x 5 |

| 14 | 2000 | 32 x 5 |

| 14 | 3000 | 32 x 5 |

| 16 | 1000 | 32 x 5 |

| 16 | 2000 | 32 x 5 |

| 16 | 3000 | 32 x 5 |

| 17 | 1000 | 32 x 5 |

| 17 | 2000 | 32 x 5 |

| 17 | 3000 | 32 x 5 |

| 25 | 1000 | 40 x 5 |

| 25 | 2000 | 40 x 5 |

| 25 | 3000 | 40 x 5 |

| 32 | 1000 | 40 x 5 |

| 32 | 2000 | 40 x 5 |

| 32 | 3000 | 40 x 5 |

| 38 | 1000 | 50 x 6 |

| 38 | 2000 | 50 x 6 |

| 38 | 3000 | 50 x 6 |

| 48 | 1000 | 75 x 10 |

| 48 | 2000 | 75 x 10 |

| 48 | 3000 | 75 x 10 |

| *Sizes can be customized | ||